Samsung Flex Fire Equipment Construction Fire Extinguishing Sprinkler Flexible Joint Apartment Type Braid Type Thermal Insulation Type Spiral Tube Type_Medi in Korea

samsungflex

- Brand:

- samsungflex

- Product Code:

- flexible tube

- Availability:

- In Stock

Fire equipment construction fire extinguishing sprinkler flexible joint apartment type braid type heat preservation type spiral tube type

The apartment-type bracket is a type of Samsung Flex sprinkler flexible joint, and the part that connects the sprinkler head is in the form of an elbow.

It allows you to adjust the height of the sprinkler head even in places with low ceiling space, and it is convenient and safe to construct.

The apartment-type bracket can be installed in an apartment or a general building, and it is more effective when used in conjunction with a flexible tube.

The apartment bracket is made of SS41 and is available in 1/2" and 3/4" sizes.

If you have any questions about purchasing Samsung Flex products, please contact us by email, such as price and quantity, and we will let you know. If you are a B2B or B2C member, you can enjoy even more special benefits. If you would like to make a purchase, please contact us by clicking on the email below. We will be happy to advise you quickly.

cs@roaexpo.com

Samsung Flex Sprinkler Flexible Joint is a product that makes work faster and easier at firefighting equipment construction sites, and secures stability and reliability after installation.

Characteristics and advantages

Constructability

- It can be bent freely even in small spaces, making it convenient for construction.

- Banding is free even in ceiling spaces with obstacles, making construction convenient.

- The height of the pipe can be adjusted according to the specified height of the sprinkler head, making it convenient for construction.

Reliability

- There are fewer joints in the plumbing, so there is relatively no risk of leakage.

- It is tested at a pressure of 56kg/om' and has no abnormalities, and it is safe even if water hammer occurs.

- The pipe material is stainless steel and flexible, so it has excellent corrosion resistance and durability, and is suitable for earthquake countermeasures.

Affordability

- By minimizing the connection part, the construction time is reduced by more than 60%, which reduces the construction period and labor costs.

- Even if there are small places and obstacles, it can be flexibly banded, so it is convenient and fast to construct.

- It is shipped as an assembly and can be constructed without a separate process such as screw processing, which is convenient and safe.

diversity

It is made in a variety of ways according to the place and use, such as commercial use, apartment use, clean room type, tube type, heat preservation type, and braid type, so consumers have a wide range of choices.

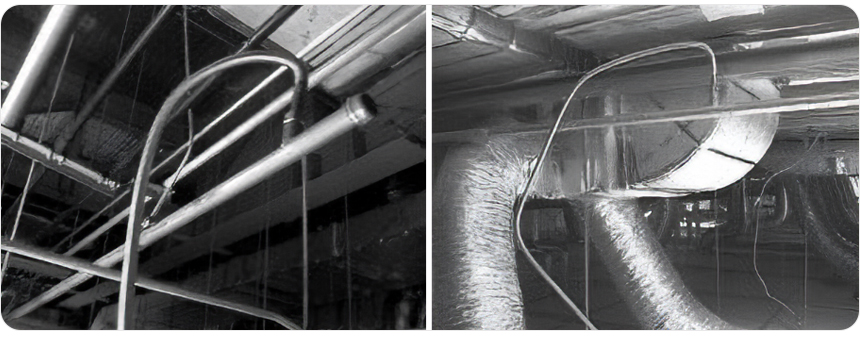

Application Case (Hyundai Asan Plant)

kind

Spiral tube

The tube is made of stainless steel, so it has excellent corrosion resistance and is the most economical product.

Insulating type

It is covered with insulation material (KS) on the tube type, so there is no need for additional thermal insulation work, so it is convenient to construct.

Braided type

The tube is braided, which is an excellent product that has a beautiful appearance and can withstand high pressure.

Apartment type

The sprinkler head connection is in the form of an elbow, so it is convenient to use it in places with low ceiling space in apartments or general buildings.

| Type (model name) | Length (mm) |

|---|---|

| Standard Type (SPU) | 500, 700, 1000, 1200, 1500, 1800, 2000, 2500, 3000 Non-standard lengths can be produced according to the customer's requirements. |

| Apartment type (SPA) | |

| Braided (SPB) |

| number | Part Name | material |

|---|---|---|

| 1 | Flexible tube | STS304 |

| 2 | nut | S20C |

| 3 | Nipple | S16C(1") (PT, NPT, BSP screw) |

| 4 | Reduca | S16C(1/2",3/4") (PPT, NPT, BSP screws) |

| 5 | Insulating ring | Nylon66 |

| 6 | Gasket | NBR |

| 7 | Braid | STS304 |

| 8 | Clamping | STS304 |

| 9 | Bracket (large) | SS41 |

| 10 | Bracket (small) | SS41 |

| 11 | T-BAR Bracket | SS41 |

| 12 | Square Bar | GI PIPE(SGCC) |

| 13 | Apartment bracket | GI PIPE(SGCC) |

| Model | Inner diameter (mm) | Outer diameter (mm) |

|---|---|---|

| SPD | 24.5 | 25.1 |

| SPC | 25.5 | 26.1 |

| SPE | 26.2 | 26.8 |

Construction method

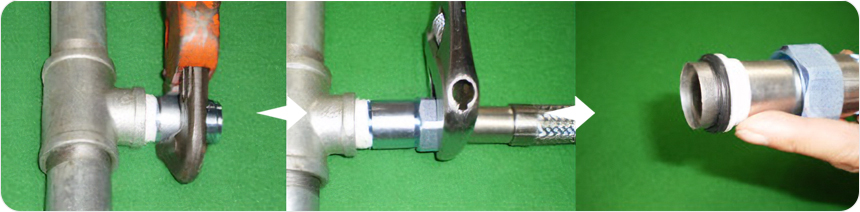

1. Install sprinkler joints on the branch wires

- Apply Teflon tape or waterproofing agent to the 1" screw of the nipple of the sprinkler joint and assemble it on the branch wire.

- Use a wrench to tighten it so that there is no leakage from the screw.

- Sprinkler joint Use a wrench to tighten the nut on the hose to the nibble.

- When assembling the hose to the nipples, make sure there is a packing to prevent leakage.

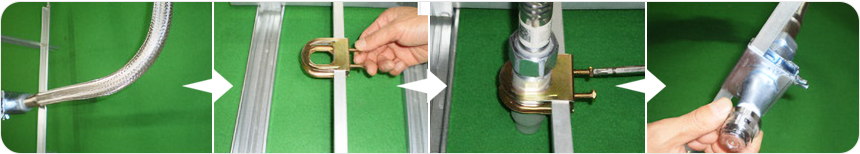

2.Square bar installation

Use a wrench to tighten the fixing bolts attached to the bracket (small) so that they do not shake the given bracket (small) and square bars where you want to install the sprinkler joint.

3. Fastening of sprinkler joints and installation of sprinkler heads

- Bend the sprinkler joints to position them.

- Install the bracket on the square bar.

- Decide the proper position and height to fix the redusha sprinkler head, then insert the reducha into the middle circle of the bracket (large) and tighten the fixing bolt with a wrench to prevent the reducha from moving.

- Apply Teflon tape or waterproofing agent to the screws of the sprinkler head and assemble the head into the reduxa.

4. Inspection after installation is completed

Once the installation is complete, check for leaks by running the water pressure.

| Test items | Test Criteria | Test results |

|---|---|---|

| Maximum working pressure | The maximum working pressure of the sprinkler joint should not be less than 14kgf/㎠. | No abnormalities |

| Pressure resistance test | Water pressure of 1.5 times the maximum working pressure (21kgf/㎠) should be applied for 15 minutes so that there is no deformation, damage, leakage, etc. | No abnormalities |

| Permanent deformation test | A water pressure of 1.5 times (21kgf/㎠) of the maximum working pressure is applied for 1 minute, and the length after 5 minutes of removing the pressure should be less than 8.4mm/m and not exceed a maximum of 31mm. | No abnormalities |

| Vibration test | With a water pressure of 1kgf/㎠, the forward width is 5mm, and the frequency is 25 times/sec, and it is loosened when vibrating for 6 hours, and there is no leakage. | No abnormalities |

| Bending test | After applying a water pressure of 0.21kgf/㎠ and repeating the bending test left and right at an angle of 90 degrees, there should be no water leakage. | No abnormalities |

| Water hammer test | After 4,000 consecutive water shots from 3.5kgf/㎠ to 35kgf/㎠ every second, apply 1.5 times the maximum operating pressure (21kgf/㎠) water pressure for 5 minutes so that there is no leakage. | No abnormalities |

| Destructive testing | It will not be destroyed by applying a water pressure of 4 times the maximum operating pressure (56kgf/㎠). | No abnormalities |

| Friction loss test | The emission factor (K) and the equivalent length should be within 5% of the application value. | No abnormalities |

There are no reviews for this product.