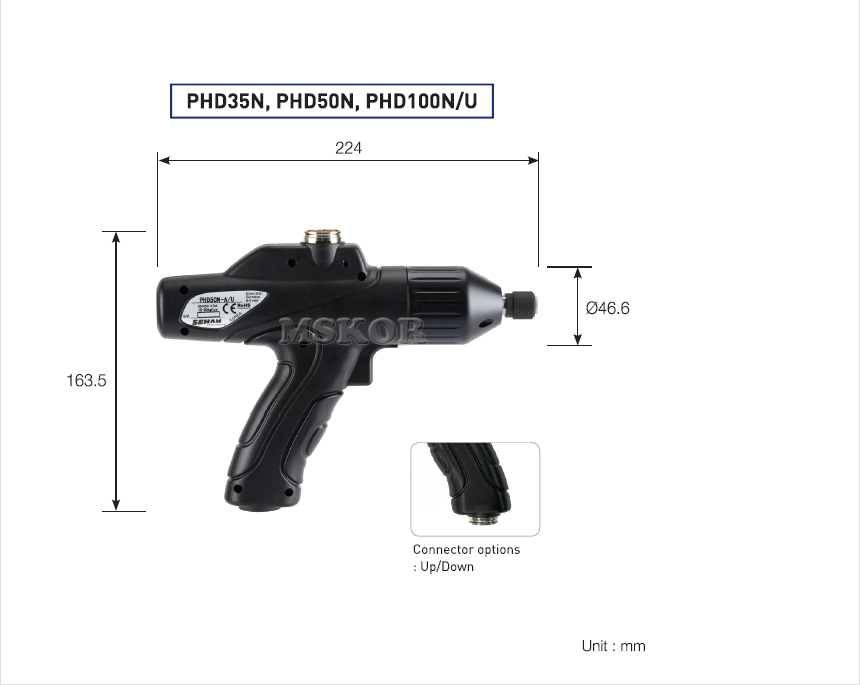

SAEHAN Hybrid Electric Screwdriver HD-N-SERIES, HD35NP, HD50NP, Push type, High Torque Electric Driver capable of Remote Control and Fastening Data Output

SAEHAN_Tools

USD $0.00

0 reviews

- Brand:

- SAEHAN_Tools

- Product Code:

- SAEHAN_HD-N-SERIES

- Availability:

- In Stock

Description

- Various data such as setting torque, tightening torque, number of revolutions, count, tightening time, etc. can be checked using a PC or DATA MANAGER. In addition, remote control and fastening data output are possible by linking with a PLC.

- Models are divided into manual and automated models depending on the usage environment, and VACUUM can be selected as an option.

- Torque, speed, rotation angle (MIN/MAX) can be saved in pre-memory up to 8 (PRESET NO.)

- Each PRESET number is simply saved and selected by the operator using a sensor.

- Easy to vary manual and automatic torque

- Easy to vary manual and automatic torque

- Secure quick workability with high-speed rotation

- Fastening error prevention system management with built-in fastening quality monitoring and counting functions

- Data management for fastening through serial communication of PC and PLC

- Abnormal operation is displayed with various error codes, enabling quick judgment and action on errors.

- Speed (RPM) automatic change setting when torque is set (manual setting possible)

- Check fastening data through RS232C communication and USB communication

- Simple operation and real-time fastening data confirmation with HI-MANAGER (PC PROGRAM)

- Firmware upgrade using serial port

0 reviews

There are no reviews for this product.

Related Products

SAEHAN Controller for Electric Screwdriver ET-30D, EF040, EF055, EF080, EF120, EF180, EF080P, EF120P, EF180P only, Power Input 110~230V (Free)

USD $66.96 USD $78.26

SAEHAN AC Direct-connected Electric Screwdriver SS180L, lever type, 220V, Rotation direction and Torque nut adjustable electric screwdriver

USD $229.57 USD $260.87

SAEHAN AC Direct-connected Electric Screwdriver SS180P, Push type, 220V, Rotation direction and Torque nut adjustable electric screwdriver

USD $229.57 USD $260.87

SAEHAN AC Direct-connected Electric Screwdriver SS250P, Push type, 220V, Rotation direction and Torque nut adjustable electric screwdriver

USD $239.13 USD $265.87

SAEHAN AC Direct-connected Electric Screwdriver SS250P-B, Push type, 5mm Bit, 220V, Rotation direction and Torque nut adjustable electric screwdriver

USD $232.43 USD $260.87